Improving Underground Fault Location

Sentient Energy Line Sensors

Sentient Energy’s UM3+ and UM1 underground intelligent line sensors can be installed in switch cabinets along feeders and in URD transformer cabinets to create more granular fault detection systems. Line sensors wirelessly report faults and periodic data to the Ample® Analytics Platform and can integrate with SCADA/OMS/DMS systems. Ample records sensor data, analyzes it over time, and provides utility engineers with system-wide insights. Accurate fault data from more locations improves distance-to-fault calculations and enables dispatchers to direct crews more effectively.

How It Works

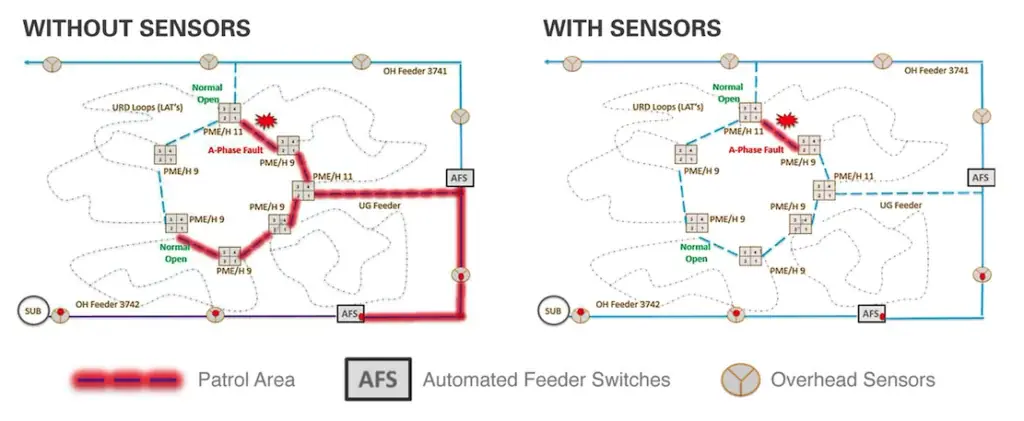

With Sentient Energy’s UM3+ and UM1 underground line sensors utilities can better isolate fault locations and reduce patrol areas significantly. The underground sensors offer:

- Accurate measurements – Underground line sensors accurately capture continuous load data as well as fault magnitude up to 10kA within +/-2% accuracy.

- High-resolution waveforms – High-fidelity fault waveform data is captured at 256 samples per cycle and made available via the Ample Analytics Platform for enhanced fault analysis.

- No maintenance power supplies – UM3+ sensors are fully line-powered with only 12A or more on just one phase, and UM1 sensors utilize AC power in transformer cabinets.

Results

Sentient Energy’s underground line sensors are field proven to improve the precision of underground fault location, helping utility crews find faults more quickly, saving costs, and enabling faster outage restoration.