PG&E Quantifying SAIDI reduction and other benefits of line sensors

The Client

Pacific Gas and Electric Company, incorporated in California in 1905 and based in San Francisco, is one of the largest combined natural gas and electric energy companies in the United States. Its 20,000+ employees provide natural gas and electric service to approximately 16 million people throughout a 70,000-square-mile service area in northern and central California, extending from Eureka in the north to Bakersfield in the south, and from the Pacific Ocean in the west to the Sierra Nevada in the east. The company’s 3,000+ feeders stretch across 141,215 circuit miles of electric distribution lines, serving 5.4 million electric customer accounts.

PG&E is at the forefront of the adoption of solar and electric vehicles while managing an aging infrastructure. The company has been a leader in enhancing its system with the most promising new utility technologies for decades. In fact, PG&E also invented many utility technologies, including communicating line sensors. PG&E concluded in a 1990’s study that its distribution grid, with increasing solar and DER penetration, would require hundreds of thousands of line sensors. Its engineers went to work and built early prototypes, filing four pioneering patents owned by PG&E to date.

The Challenge

Having a head start in understanding the potential of line sensors, PG&E had been tracking the development of products in this space for many years. It became clear that line sensors could be instrumental in helping PG&E continue to improve its reliability statistics while supporting an increasing penetration of solar and electric vehicles. While line sensor technology was maturing in the market place, PG&E secured CPUC funding and in 2014 embarked on the most comprehensive test ever undertaken in the utility industry of available line sensor products. The test concluded with very positive results in 2016.

The Project

The PG&E project targeted the evaluation of line sensors capabilities, including robustness and fit with various use cases Most importantly, it wanted to quantify the achievable SAIDI savings from line sensors for the fundamental business case that could justify their deployment. However, the PG&E team did not stop there. They also tested and evaluated the communications and advanced capabilities of the available products. These included the ability to communicate over PG&E’s Silver Spring mesh communications network, the capturing of detailed oscillography of faults and other grid events, and the ability to help with DER deployments via detection of current direction and related capabilities.

PG&E’s tests consisted of a lab test phase and a field test phase. During the lab test phase, specific features and capabilities of all products were tested extensively and benchmarked against each other. This included environmental tests such as sensor operation in fog, under snow and ice, in dust, and even submerged in water. The sensors were also run through a battery of tests to confirm their fault detection, fault magnitude measurement, and fault waveform capture capabilities. One key conclusion from these lab tests was that all products supported the basic capability of immediate fault detection and alarms over the cellular network. Sentient’s MM3 was the only product to demonstrate that capability via either cellular or the Silver Spring mesh network.

Figure 1: PG&E field test of Sentient Energy line sensors. Here line sensors are installed next to some of the 200,000+ mechanical FCIs PG&E has in place today. Line sensors are designed to replace these FCIs as a much more capable instrument.

Figure 2: PG&E’s Diagnostic Center Team reviewing line sensor information.

In the field test phase, PG&E deployed almost 1,000 line sensors, on numerous feeders throughout the distribution grid, and monitored the equipment’s performance for almost five quarters. This phase fully involved PG&E’s engineering and operations teams. Line sensor measurements were displayed on the dispatcher’s screens. Specifically, line load and fault data was instantly visible to operations personnel. In addition, more advanced data such as fault waveforms captured by the sophisticated line sensors under test, was routed and analyzed by a “Diagnostic Center” team assembled solely for this purpose.

The Benefits

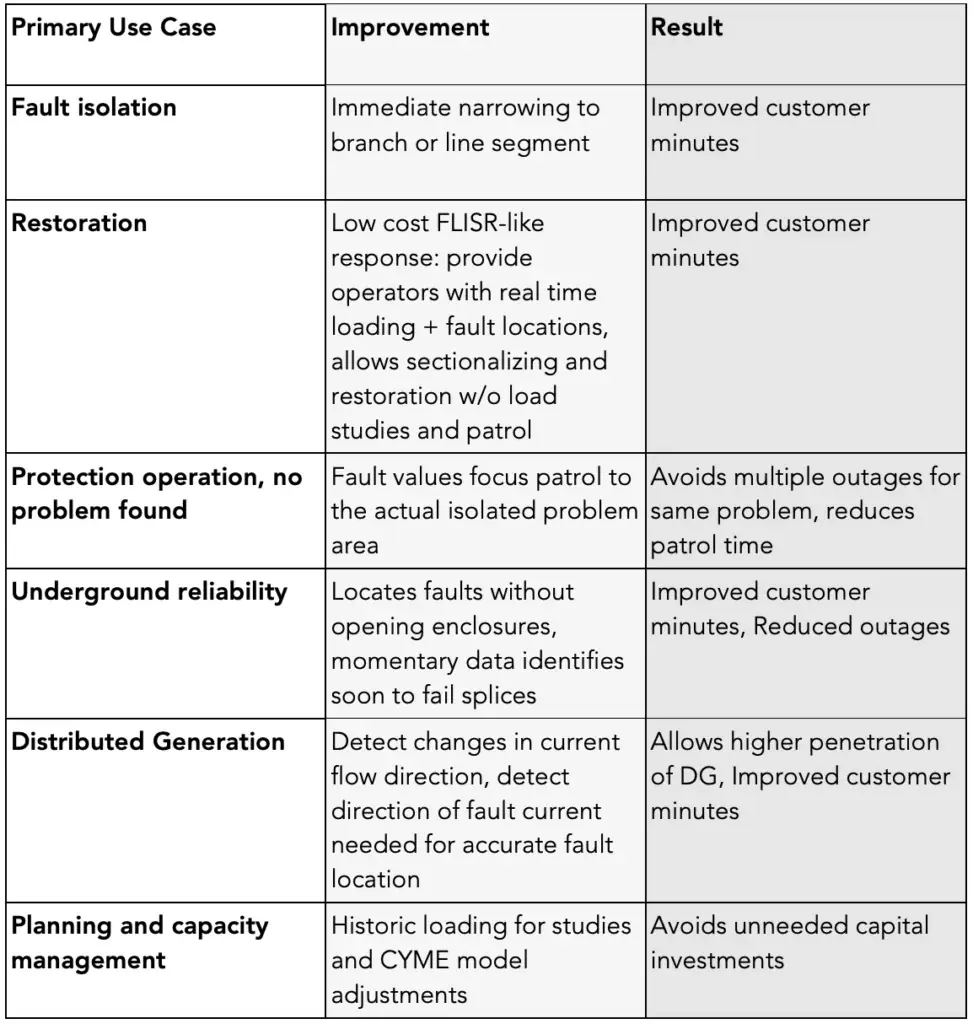

PG&E’s team identified a number of primary use cases with specific benefits for line sensors were found to be useful for more than fault isolation and restoration. Getting real time information from the field also helped with protection operations that occurred while no trouble was found during follow-on patrolling: line sensors helped reduce patrol time in those cases, and also avoid multiple outages caused by the same problem. An overview of all primary use cases PG&E identified and their benefits are shown in the table below.

Advanced Functionality

PG&E also spent considerable time and effort investigating and testing advanced features of line sensors. For DER integration, the team tested the ability of the line sensors to detect load direction and correctly resolve fault location on circuits with heavy solar penetration. PG&E determined that line sensors again helped reduce CMI while also supporting a higher DER penetration. Furthermore, they found that high resolution oscillography of fault waveforms was useful for fault cause categorization, and for indication of future failure risks, such as issues with capacitor-bank operations. PG&E also concluded that waveform capture harbored significant potential for future use cases, such as high impedance fault detection. With oscillography, such a foundational capability for advanced applications, in its final report the team concluded that the higher the waveform resolution, the better.

Sentient MM3 line sensors offer the highest waveform capture resolution currently available from any line sensor, and are ready to support all the advanced functions investigated at PG&E.

Compelling Line Sensor Business Case: Customer Minutes Interrupted (CMI) Reduction of nearly 20%

The key conclusion from PG&E’s trials was that the business case for line sensors is compelling. As the field trials showed, CMI could be reduced as follows:

- 12.6% reduction from saved patrol time

- 18.0% reduction with SCADA switching

- 19.4% if the line sensor information was combined with calculated fault location

About Sentient Energy

Sentient Energy makes electric power delivery safe, reliable and solar ready. Sentient Energy offers the Utility Industry’s only grid analytics system that covers the entire distribution network with intelligent sensors that are quick and easy to deploy, as well as analytics that detect and analyze potential faults and other grid events that can disrupt electric service or present potential hazards. We lead the market with the largest mesh network linesensor deployments in North America, and partnerships with leading utility network providers including Silver Spring Networks, Landis + Gyr, Cisco, and AT&T.

Visit www.sentient-energy.com.