Improving ADMS Distance To Fault Calculations

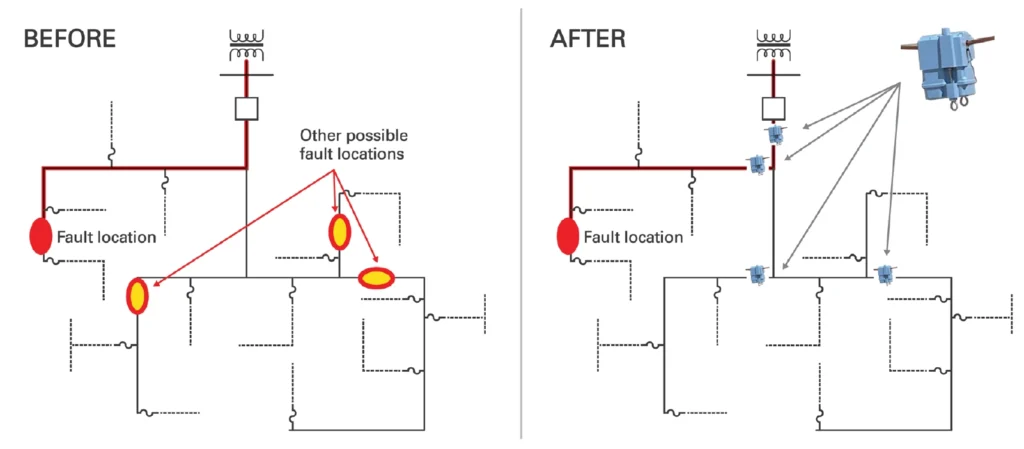

Advanced Distribution Management Systems (ADMS) combine impedance models, fault magnitude data, and sophisticated equations to determine possible fault locations. If fault detection and fault magnitude data are only available at the substation the ADMS will project multiple possible fault locations on highly branched distribution circuits. Crews will need to patrol several areas to find the fault.

Sentient Energy Line Sensors

Sentient Energy’s intelligent line sensors can be added to the distribution system at locations where the system branches. These sensors detect faults and wirelessly report data to the ADMS which can refine distance to fault calculations. With additional data from more locations the ADMS can zero in on the actual fault location.

How It Works

With Sentient Energy’s MM3ai and ZM1 overhead line sensors and UM3+ and UM1 underground sensors, utilities can integrate more fault detection location data points into their ADMS. These sensors offer:

- Accurate fault magnitude measurements – Sentient Energy line sensors accurately capture peak fault current magnitude up to 10kA within 2% accuracy.

- Identification of ground faults – MM3ai sensors and Ample can distinguish between phase-to-phase and phase-to-phase-to-ground faults. Depending on the feeder, this distinction can significantly improve fault location.

-

ADMS integration – The Ample Analytics platform has an application programming interface (API) to facilitate integration of sensor data into a utility’s ADMS.

Results

Sentient Energy intelligent line sensors have been proven in the field to improve the effectiveness of ADMS distance to fault calculations used to help crews locate faults quickly and for automated ADMS fault isolation and restoration schemes (FLISR/FDIR/FISR).